Case Study

Plymouth North High School

Plymouth, MA

Saving through innovation

Plymouth North High School is the first LEED certified Platinum educational building operating as a net zero facility, generating all of its own energy in New England. Currently, it is one of only three such high schools in the United States and has been operating since September of 2012.

This beautifully elaborate structure was architecturally designed to resemble Plymouth’s original high school’s Federal classical appearance. This 268,000-square-foot, $83 million project includes an extensive library, oversized gymnasium, auditorium, laboratories, television studio and state of the art classrooms.

The Team

The design team included local firms Ai3 Architects LLC and Griffith and Vary Inc. who designed the state of the art mechanical systems.

The team performed an extensive site analysis and incorporated many sustainable “green” design elements into the building such as a 100kW photovoltaic solar array, rain-collection system for grey water systems, lighting sensor system that shuts off lights when rooms are unoccupied and a well-insulated building shell that will reduce heating and cooling costs dramatically. The property also features electric car charging stations in parking lots, interactive kiosks at the entry lobbies and day lighting in all the classrooms.

HVAC Technology

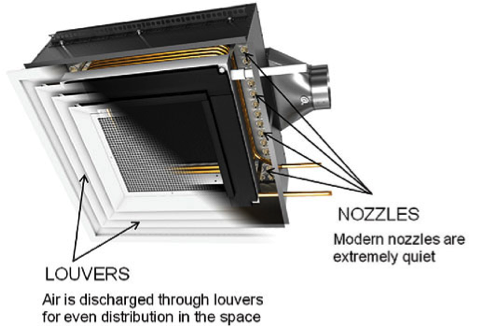

The buildings HVAC system includes NuClimate (A Zehnder Rittling Company) induction beams located throughout the facility providing heating, cooling and fresh air to each of the spaces while reducing the facilities overall fan energy by 66% as compared to other conventional systems. These units range in size from 2’x 2’ to 4’x 4’ and have no internal moving parts.

NuClimate’s induction beams receive primary air supplied by air handlers which is distributed through a bank of specially designed aerodynamic nozzles. The air is then discharged at high velocity into a mixing chamber creating a pressure differential that enables room air to be drawn across the conditioned coil.

The primary air and induced air are then mixed and discharged through a grille in a coanda effect air distribution at the ceiling level. The total room air circulation is created solely by the induction principle within the terminal unit and eliminates the need for an electric motor and or power source. Ultimately the result in a very quiet and efficient way to provide superior comfort for occupants.

Ceiling Integration

The induction beams seamlessly integrate into the ceiling architecture while providing heating and cooling to the classrooms with unparalleled consistent temperature and humidity control. The set point temperature of the classrooms is remotely controlled with additional local control for teachers and are maintained within a half of a degree off set point. These cost effective terminal units thoroughly mix room air eliminating cold spots in rooms while providing an excellent environment for learning. In addition to the energy savings and enhanced IAQ benefits of the HVAC system, there is no cross contamination of air passed from room to room through the buildings HVAC ductwork. All spaces exhaust air exits the building once the energy is recovered.

Chris Hastings, the district’s energy conservation coordinator, said the project has had a positive impact throughout the district. After seeing how efficient some of the new mechanical designs are, the district has started retrofitting systems in the town’s other 13 schools.